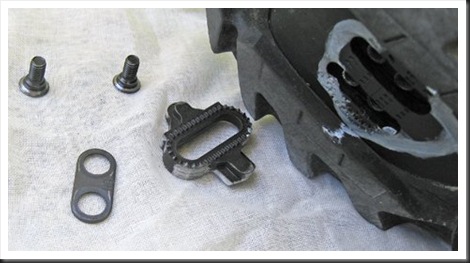

(Picture for illustration only, not the actual part)

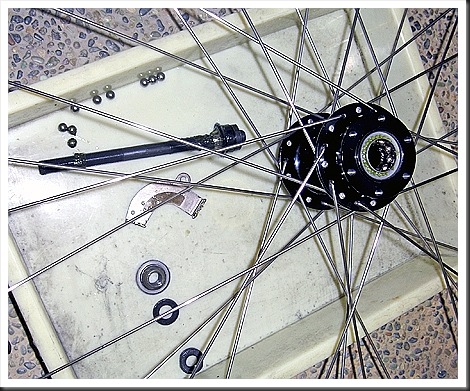

The bicycle axle is a critical component that must endure high repeated cyclic loads especially from imperfections on the road.

Fatigue is when a motion is repeated, the object that is doing the work becomes weak. Just like cycling, our legs become slow and weak after a while. Same principle for materials. Fatigue occurs when a material is subject to alternating stresses, over a long period of time. The axle holds our body and bike weight. When we pedal, the chain tension loading and road shock/ vibration put lots of stress on the axle especially at the inner side of the right bearing cone (cassette/gear side). This location according to some veteran is where axles usually "bend" as they crack.

Initial symptom: Shaky rear wheel

Initial suspect: Loose hub – cone nut came loose due to terrible road imperfection/ vibration from KT ride.

Action taken/ Observations:

Removed Quick-Release skewer and rear wheel from the bike.

- Finger able to rock the hollow hub’s axle side to side (approx 3-5 mm)

- Left (non-drive) lock nut was already loosen. Able to turn nut with fingers.

Attempt to adjust loose axle :

- Finger-tighten, turned in cone nut to touch bearings.

Axle still rock side to side. No significant improvement especially on drive side.

- Clean bearings and applied grease on non-drive side

- Adjusted cone & tightened non-drive lock nut. Drive side still rocking.

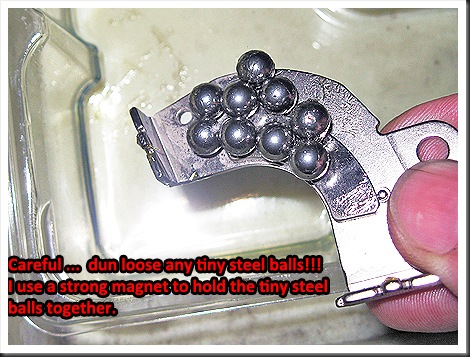

- Tried to remove cone and lock nuts on drive side to check for missing steel balls.

=> Top half of the axle just came off with just a little loosening force applied on the lock nut. The axle broke along the threaded section on the inner side of the right bearing cone as shown on the picture above.

Possible causes:

Each thread valley is a stress concentrator, repeated cyclic stresses over many km, over a long period of time, the axle can fatigue at one of the thread valley and a crack may begin to propagate through the axle. It is most likely that the terrible vibration caused by the ‘rough’ KT road escalated the crack propagation.

The fracture surface if I remember correctly, half or more is smooth. Smooth fracture surface is a result of continuous rubbing of the crack as it grows. The crack appears to have propagated to about half or more of the axle diameter thus the possible side to side rocking. The smaller rough fracture surface is the breakage point possibly from the twisting force used to loosen the lock nut.

My thoughts:

Next time before and especially after a rough ride, make sure check for no shaky wheels among other things. Lucky the axle lasted all the way home, or else jialat. Possibly the quick-release skewer that goes thru the hollow axle was all the while helping to hold the axle together … axle compression when we tighten the wheel, skewer rod inside the hollow axle holding it straight… until when we removed the wheel and pulled the skewer rod out of the hollow axle … all hell broke loose!